My Role at Abas USA

At ABAS USA, I worked as a software developer specializing in both backend and frontend development, with expertise in building enterprise mobile app software solutions for mid-market manufacturing and distribution companies. Beyond my development duties, I also acted as a user centric consultant, ensuring the apps I built aligned with user needs.

My role included traveling to clients, attending industry events, providing training, explaining the app’s value, and collecting user feedback to refine the products further.

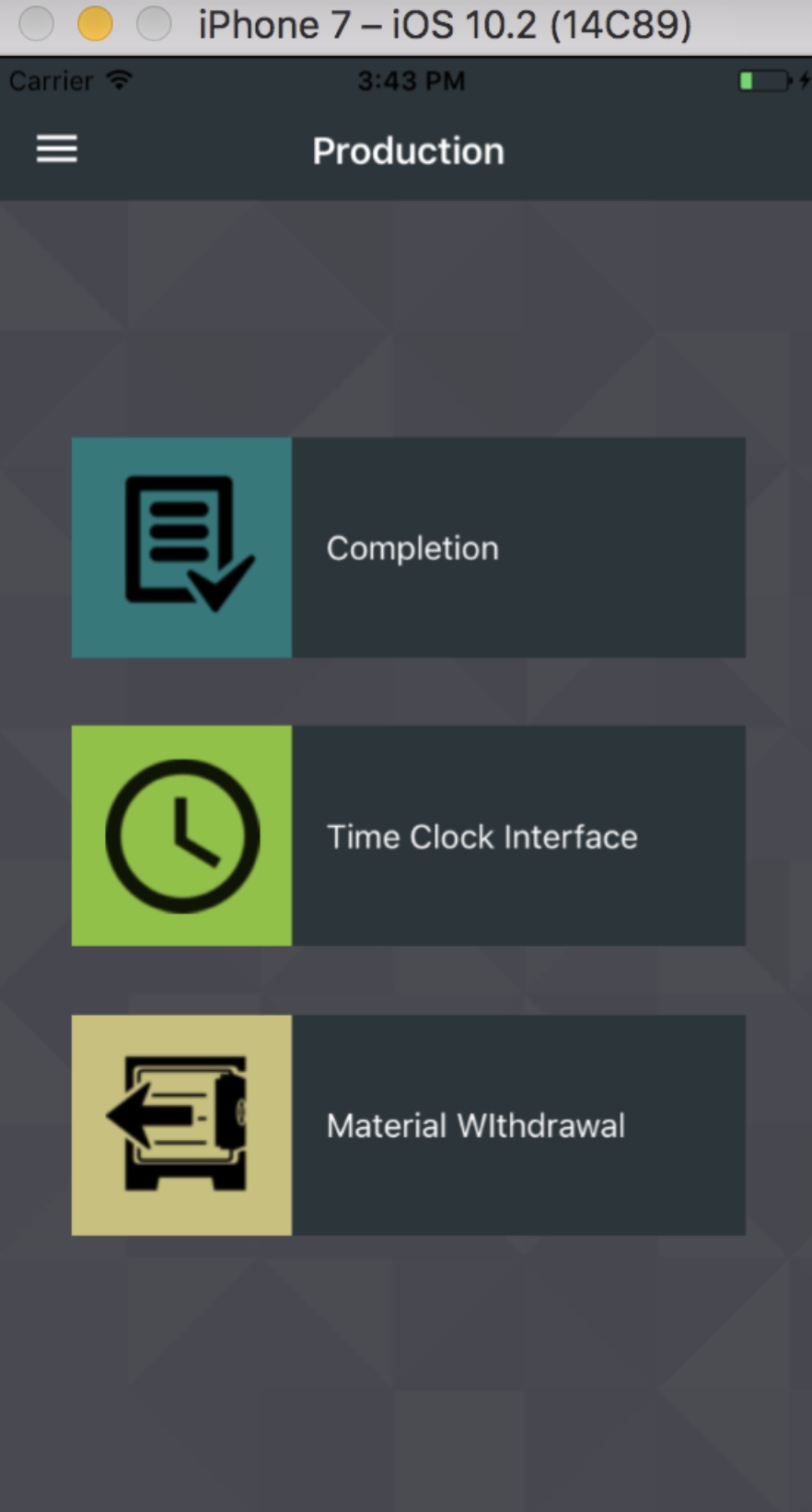

I was responsible for creating three key mobile applications using Xamarin: Inventory, Production, and Receiving. These applications streamlined warehouse operations, improved data accuracy, and enhanced the overall efficiency of warehouse staff by digitizing manual processes. Below are case studies for each of the apps she developed.

Case Studies

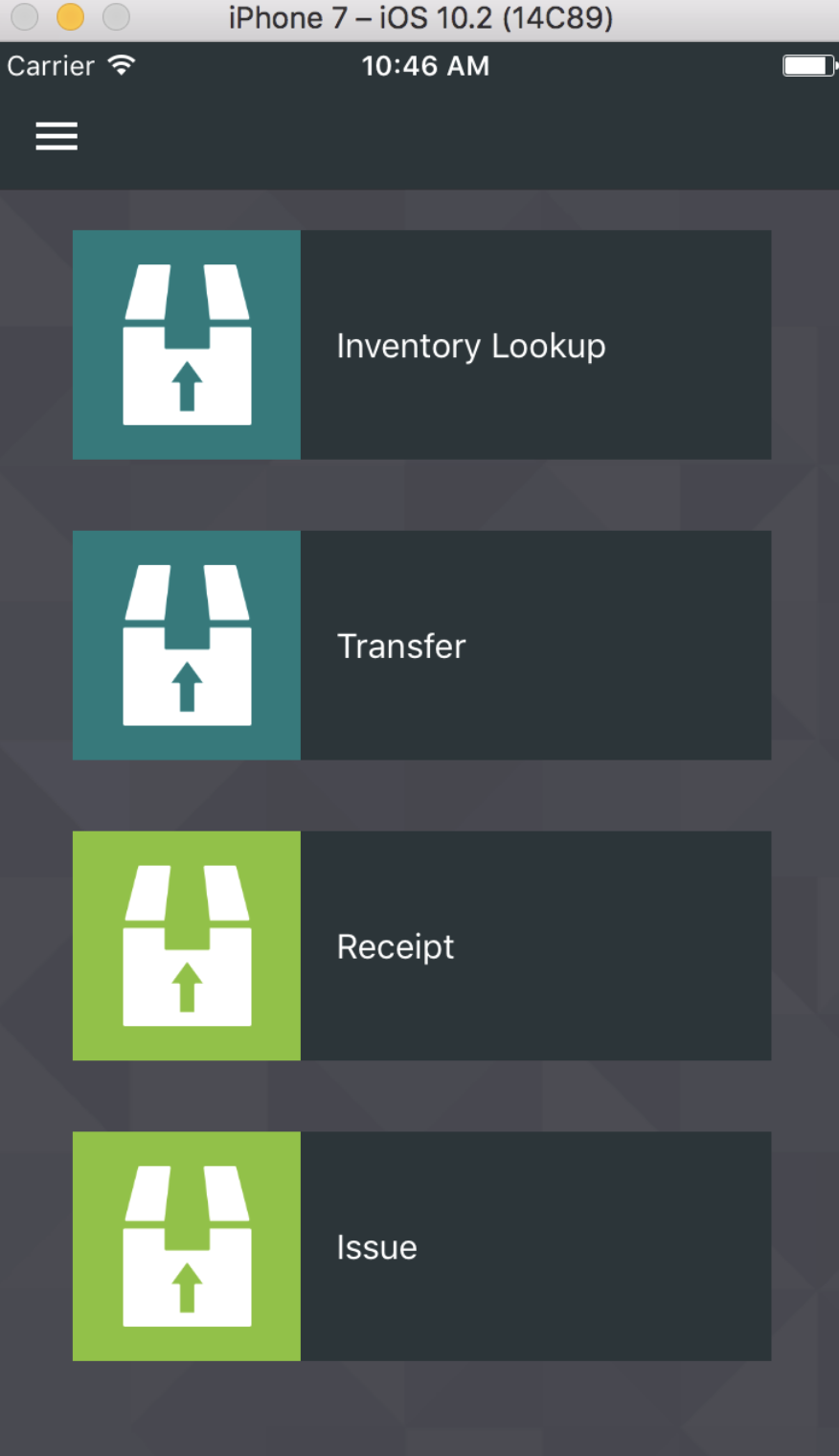

Case Study 1: Inventory Management App

Background & Problem

In our clients’ warehouses, manual inventory tracking was leading to inefficiencies and inaccuracies, including misplaced goods, stock level mismatches, and slow restocking processes. The company needed a solution to streamline the inventory tracking process and eliminate the errors caused by manual data entry.

Key Features

Real time updates: Changes in inventory were instantly reflected in the warehouse’s central database.

Barcode scanning: Integrated barcode scanning allowed for fast, error-free stock management.

Low stock alerts: The app provided alerts when inventory levels fell below predefined thresholds, helping to prevent stockouts.

Analytics and reporting: Managers could generate real time reports on stock levels, movement history, and stock usage trends.

Impact

Reduced errors: Manual entry errors dropped significantly, resulting in a 30% improvement in inventory accuracy.

Faster processing: The time required to update stock levels was reduced by 40%, improving overall warehouse efficiency.

Higher employee satisfaction: Users appreciated the app’s simplicity, which increased engagement and reduced the time needed for training.

Solution: Inventory Management App

I developed the Inventory Management App from the ground up using Xamarin, specifically tailored to the needs of the warehouse. The app allowed staff to quickly scan barcodes, update stock levels in real time, and track the movement of inventory within the warehouse. I focused on creating a clean, intuitive interface to ensure that non-technical staff could easily adopt the app.

Background & Problem

The manufacturing process required manual tracking of work in progress items, which caused delays in updating the status of production tasks. The warehouse needed a more accurate and real time way to track production stages.

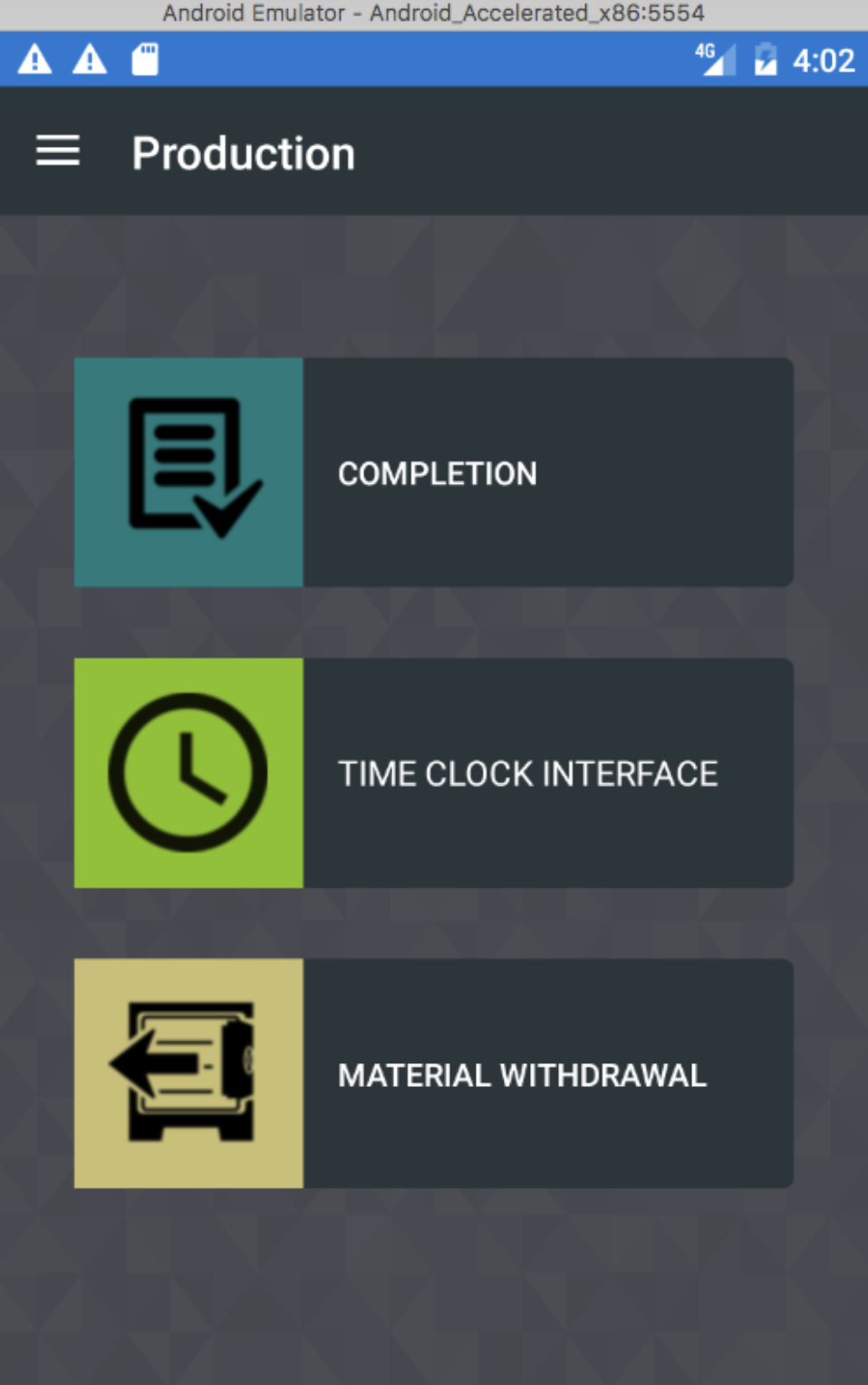

Case Study 2: Production Management App

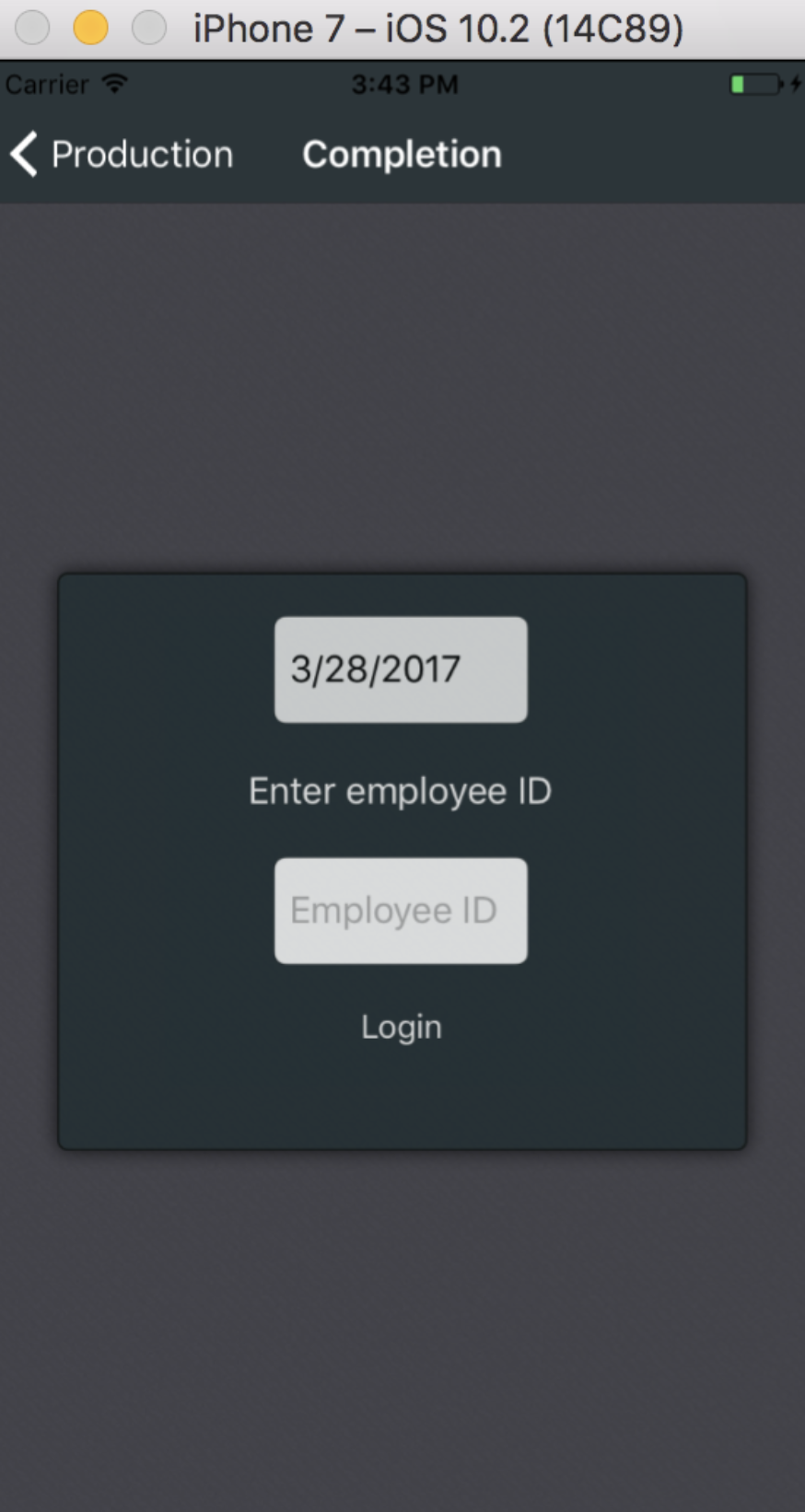

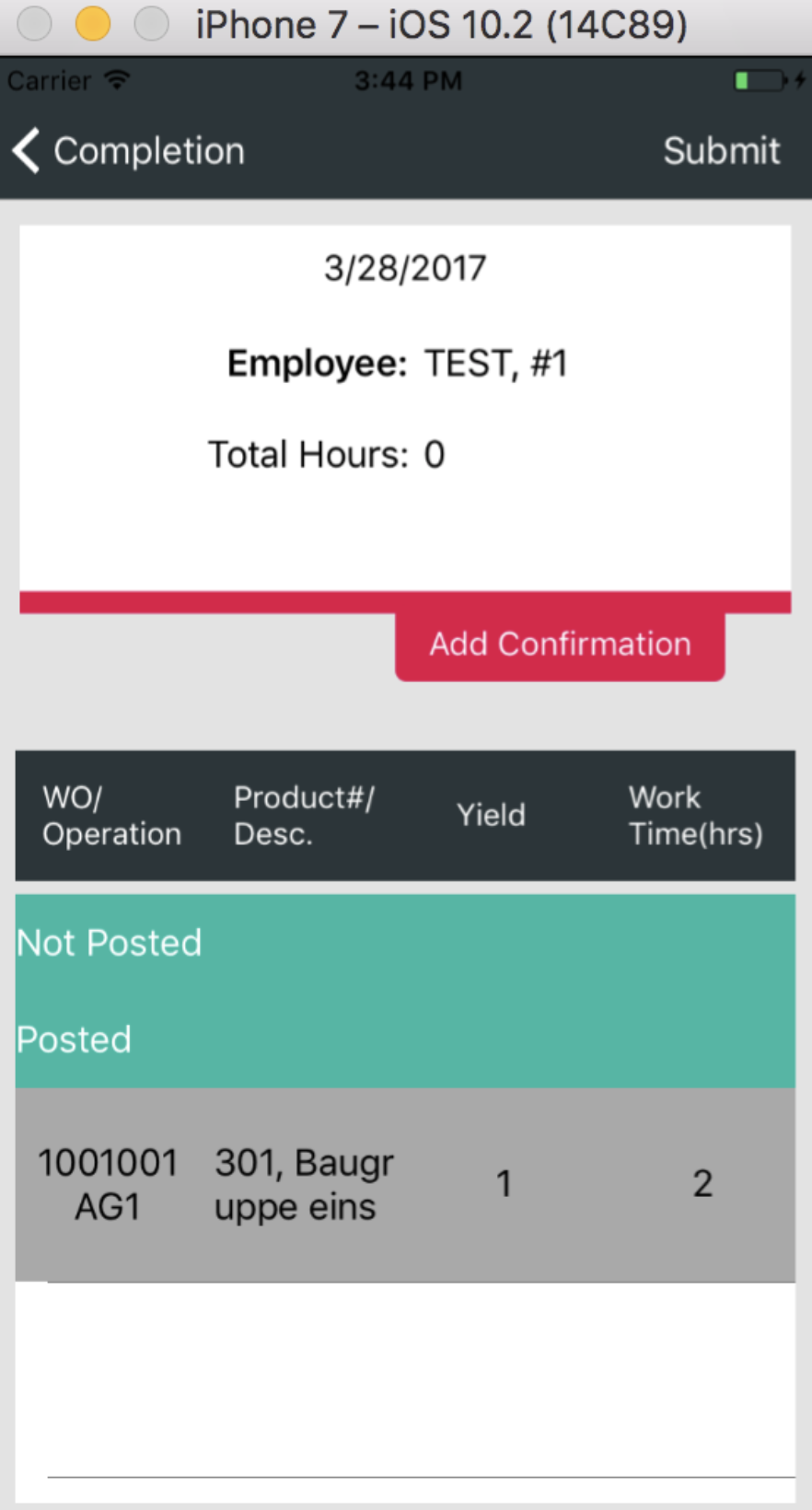

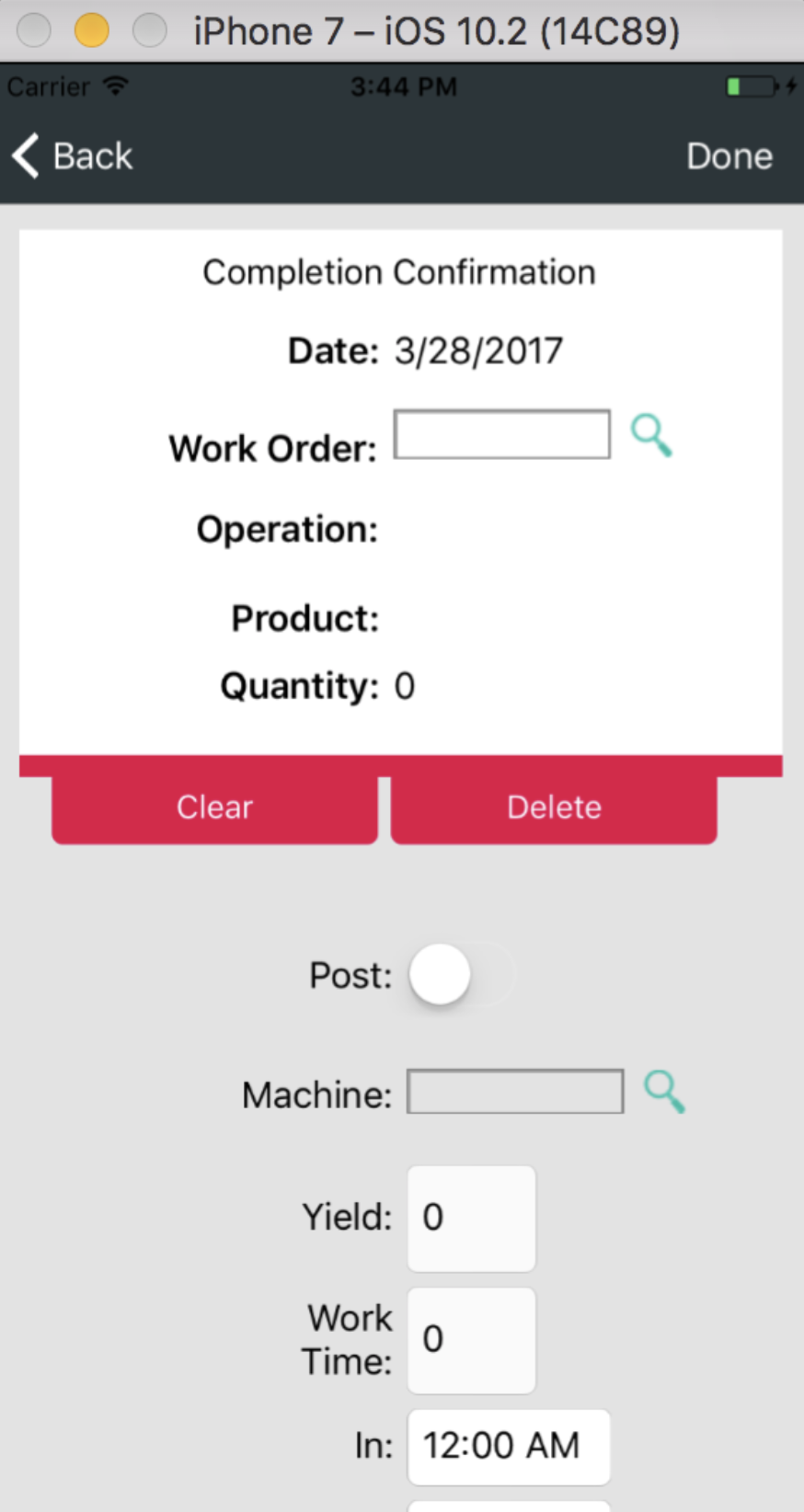

Solution: Production Management App

I created the Production Management App to automate and optimize the tracking of production stages. The app allowed staff to update the status of tasks, track items as they moved through different stages of production, and view real time progress on a visual dashboard.

Key Features

Task status updates: Staff could update the status of production tasks in real time, and the changes were reflected system wide.

Progress tracking: The dashboard allowed managers to monitor the progress of items through various production stages, helping them identify bottlenecks.

Job prioritization: Jobs could be reprioritized based on real time data to ensure that urgent tasks were completed first.

Time tracking: Automated logging of time spent at each stage provided valuable insights into production delays.

Impact

Improved production visibility: Managers gained real time insights into production bottlenecks, leading to a 25% reduction in delays.

Streamlined processes: Automating task updates reduced manual input by 50%, allowing staff to focus on higher value tasks.

Increased production speed: By optimizing the workflow and enabling better task prioritization, production speed improved by 20%.

Background & Problem

Receiving shipments was a slow, labor intensive process involving multiple manual steps. Paper forms were used to track goods received, which often led to data entry errors and delays in updating the inventory system.

Case Study 3: Receiving Management App

Solution: Receiving Management App

I developed the Receiving Management App, which digitized the entire receiving process. The app allowed staff to quickly scan items as they arrived and automatically updated the system with the relevant data. This streamlined communication between the receiving team and inventory management, ensuring real-time updates to stock levels.

Key Features

Barcode scanning: Items were scanned upon receipt, instantly updating inventory records without the need for manual data entry.

Automated data entry: The app auto populated fields to reduce human error.

Shipment tracking: The app tracked shipments and matched them with purchase orders, ensuring nothing was missed or overlooked.

Receipt confirmation: Digital confirmation of receipt was generated and sent to the inventory management system immediately after items were logged.

Impact

Faster receiving times: The app reduced the time required to log new shipments by 35%.

Reduced errors: Automated data entry reduced data entry errors by 40%, leading to improved accuracy.

Improved coordination: Real time updates allowed the inventory team to adjust stock levels promptly, preventing discrepancies between received and recorded inventory.